Although mentioned previously, we’ve had to put it aside while working out where everything else is going to fit. As you know, the Curtis has a bunch of MOSFETS inside, ‘sinked’ to the base of the housing. Although efficiency can be improved in a controller design, simple immediate solutions can involve better cooling. Some folks attach the controller to a suitable flat metal surface on the car which in effect becomes a giant heatsink while others add fan arrays on top, or do both. Chunky Curtis heatsink fins are also available.

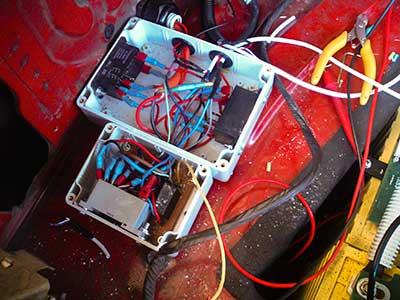

With space at a premium, a flat aluminum cooling block is used instead, fixed to the underside of the controller. In my case, the cooling block has been made to sink the heat from this area with the help of conduits drilled through the block for coolant ingress.

A pump is used to circulate coolant through the Curtis and my old interior radiator, with a return hose to the pump and an overflow reservoir with possible expansion valve (we are yet to test expansion for this amount of coolant; some thoughts below). The block itself is screwed to the base of the Curtis and thermal heatsink compound is applied between the surfaces, such as good quality silver compound for high thermal conductivity. At present it’s just a chunk of aluminum; I wonder if it should be anodized to 5> microns for better heat sinking? Better still, a block fabricated with an optimized fin-array would be nice but that may be over doing it. I have a couple of other ideas about flow but haven’t CAD’d them up yet.

Anyway, liquid cooling is much preferred over affixing bulky fans and jutting heat sinks, and is more effective. If there was room, both options could be possible, with a temperature sensor to cut in the fans – but correctly-configured liquid-cooling may negate the necessity of added thermal solutions altogether as it should allow extended peak times under load and therefore higher continuous operation – great for those steep hills etc.

Pump Action

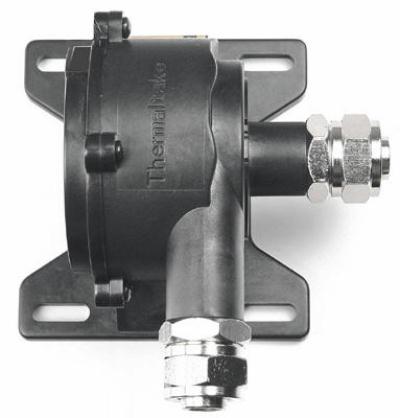

What type of pump? One that’s typically used for water-cooling fast processor chips, from Xoxide. It’s pretty robust and will run off the accessories. Clear hoses will be used so we can see the coolant.

Not much to look at, but simple and well built makes it last.

Continue reading →